HOW IS INDUSTRIAL CAKE PRODUCTION MADE, WHAT ARE THE STAGES?

In our previous article, we explained what kind of work should be done by those who want to produce industrial cakes and how they can create a budget. In this article, we will talk about the stages of cake production.

There are 2 alternatives for cake production, one of which is the fully automatic tunnel oven cake lines, and the other is the rotary oven cake lines where the pans are fed into the oven by human power (manually) and emptied from the oven by human power (manually).

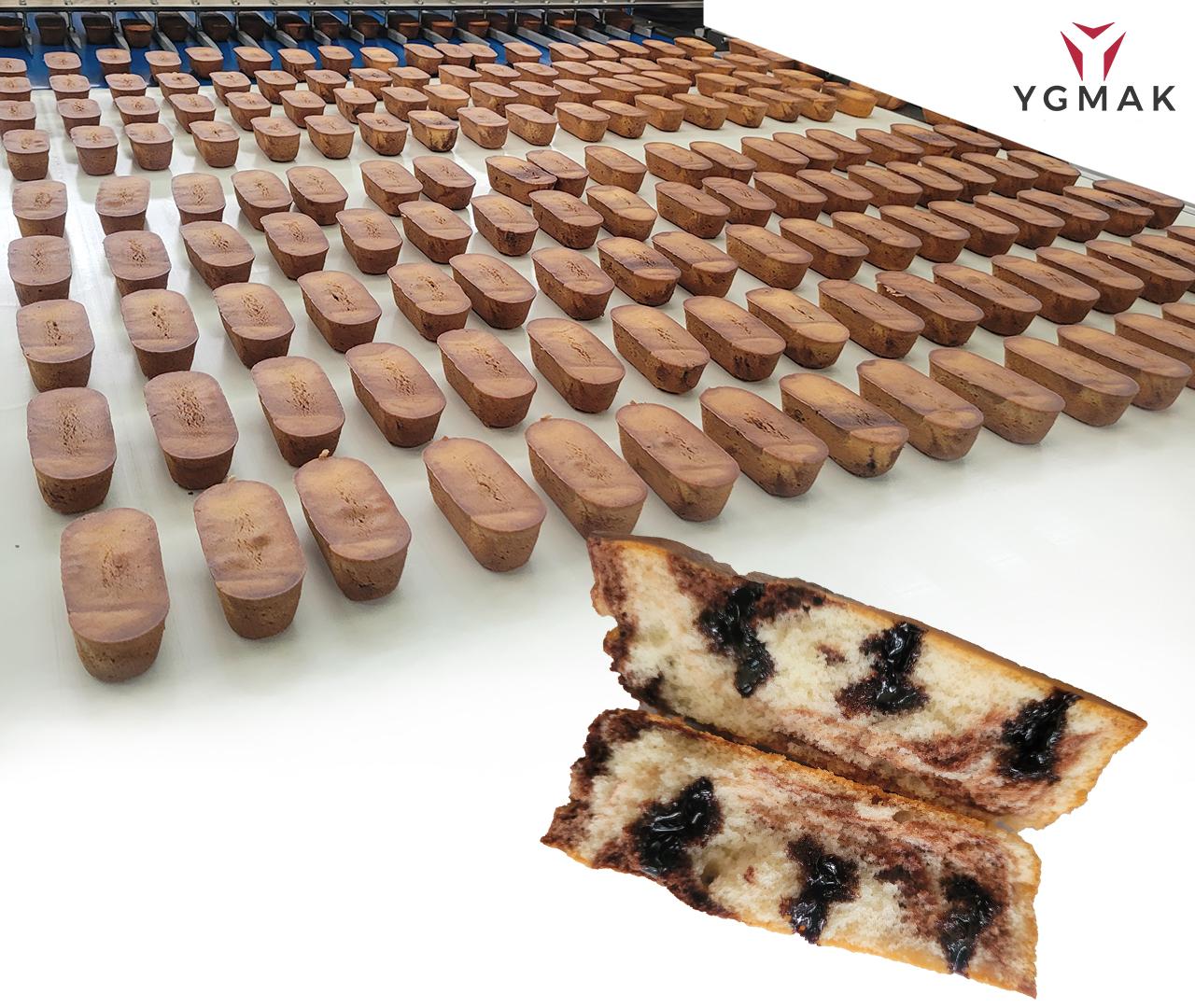

In tunnel oven cake lines, people are only for control and management purposes. All other stages are performed automatically. Only in the kitchen part raw materials are added manually. In companies with more than one line, it may make sense to automate this as well. Cake dough is obtained by adding flour, egg, etc. ingredients and some preservative raw materials in the mixers in the kitchen. This dough is transported by stainless steel pipes with double jacket. In these lines, cake production pans make loop and pass-through certain stations. First, the inside of the pan is thoroughly washed and cleaned, then some oil is sprayed into the pan and is made ready for dough. The desired weight of cake batter is filled into the oiled pans from the dough depositor and the pans continue on their way to the oven. These ways are made of stainless materials and are designed not to damage the pans. The pans, which are formed into groups of 2, 3 or 4 at the entrance of the oven, are pushed into the oven. Small-weight cakes come out of the oven in an average of 20 minutes, while large loaf cakes, which can be consumed by slicing for the whole family, are baked in 45-50 minutes. The weight and structure of the dough placed during the baking time of the cakes are effective. The cakes coming out of the oven are taken from the pans with vacuum absorbers or pin holders and placed on the belt. Apart from these, there is another system that empties the cakes inside pans by turning the pans upside down. These systems can be used according to the direction the cakes will stand on the belt. Since the cakes placed on the belt are very hot, they should cool down at room temperature for a while. Before this cooling process, if desired, sauce is pressed into the cakes. This sauce can be pressed to the desired points in the desired number by means of the needles that go into the cakes. After this station, the cakes travel on polyurethane belts for a while to cool down at room temperature. When they reach the desired temperature, they are passed through the chocolate coating station. In this coating machine, if desired, only bottom or only top side chocolate can be coated. If desired can be coated fully. If there is no chocolate coating then the cakes pass through this machine without coating. After the chocolate is covered, a cooling tunnel is also needed. The inside of this tunnel is at a temperature of 10-12 °C, and the freezing of the chocolate on the cakes is provided here. If it is too cold inside the tunnel, your chocolates will look dull or whitened. Therefore, good cooling is as important as a good coating. The cakes, which are completely ready to be packed, are sent to the packaging machine automatically. Here, the cakes lined up with belt systems can be packed individually or in groups of 2. After packaging, the expiry date and production date are coded and they come out of the packaging machine. The cakes taken in boxes are stored and sent to the markets to be delivered to the consumer.

The point that separates the rotary oven lines from the tunnel oven is that the pans do not enter and exit from the entrance and exit of the oven. These ovens are opened from a single place with a cover like the ovens in our homes. Large pan trolleys with pans are placed in these ovens, their lids are closed and cakes are baked. After the cooking process is completed, pans are taken from the oven again and are fed manually under the pan unloading units. Afterwards, the cakes are emptied from the pan by using vacuum, needles or pan inversion method as in the tunnel oven line and the other steps can be applied in the same way.

There are several important points in cake production. Cakes are much more sensitive than products such as biscuits and wafers due to the moisture content and eggs they contain. If you do not create a proper environment, your cakes will soon start to mold or start spoiling, which can cause you a lot of damage. First of all, there should be no hand contact with the cakes, if the surface of the cake is touched at one point, the cakes will start to spoil from these points. Another factor is ventilation and air conditioning. The spot where the cake production line is located should not see sunlight and should be regularly fed with air-conditioned fresh air. And this air should always be kept at room temperature. If these conditions are met, it is a very easy product to produce.